Since 1983, PHYSAN has been developing a real knowledge in yeast processing technologies.

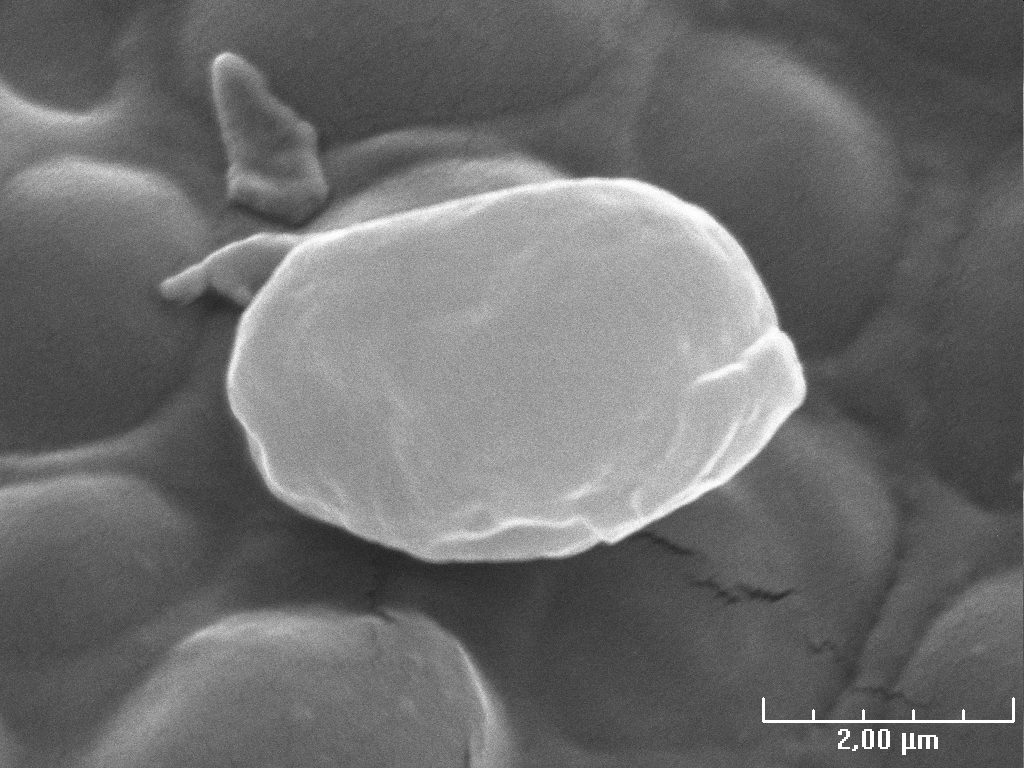

Our leading product is a saccharomyces cerevisiae bakery yeast complex, inactivated during the liquid heating phase, liberating all the specific micro nutrients by breaking the yeast cell wall, making them bioavailable in the digestive tractus.

Yeast inactivation process

- Unique process carried out over several days

- Specially selected temperature stages

- Preservation of all nutritional characteristics

- Ensured biological efficiency

1-MULTIPLICATION

This crucial stage requires perfect timing and the adding of exact quantities of high added value ingredients.

2-SELECTION

Saccharomyces cerevisiae strain selected for its natural palatability.

3-GUIDED THERMOLYSIS

Long and continuous low-temperature thermal treatment that preserves all essential nutritional elements.

4-STABILIZATION

Two processes enable the preservation of the protein, vitamin and mineral profile. Highly bioavailable ingredients that can be easily absorbed.

Benefits of inactivated yeasts :

-

- Microbial protein intake

- Highly available peptides and nucleotides

- Rich in vitamins from the B group

- Pre-biotic effect

- Natural palatability

- Optimized performance

Our inactivated yeasts

LEVULYSE

Our leading product LEVULYSE, is a 100% saccharomyces cerevisiae bakery yeast complex, inactivated during the liquid heating phase, liberating all the specific micro nutrients by breaking the yeast cell wall, making them bioavailable in the digestive tractus.

LEVULYSE MICRON

LEVULYSE MICRON is the liquid emulsified version of LEVULYSE, for using in the drinking water of poultry.

PHYSA LSC

PHYSA LSC is the powder version of LEVULYSE, to be incorporated to the feed.